The Design Museum, The Future Is Here: A New Industrial Revolution

|

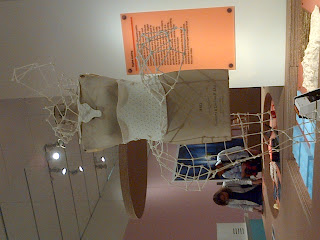

The Feathered Shoulder & the Corset and DNA components designed by Catherine Wales also produced by Digits2Widgets.

Theses were inspired by Identity and the visual structure of human chromosomes.

The DNA is created completely with individual and interchangeable ball and socket components

which allow it to be build in a variety of directions. Theses were produced using a 3D printer and

white nylon. The eight piece collection encompasses a scaffolded corset, a blossoming feathered shoulder piece and waist bracelet completes by four transformative headpieces that camouflaging key parts of the face.

3D Printed Objects:

- Titanium chainmail sample

- Cranial plate

- Ball within ball within...

- Model of lungs: Created and produced by 3T RPD Ltd

- Heat exchanger: designed using within enhance software produced by 3T RPD Ltd

- Trophy: Designed by Lionel Dean produced by 3T RPD Ltd

- Clone lights: designed and produced by Digits2Widgets

- Bird house: designed by Saint H and produced by Digits2Widgets

- A set of skulls: 3D printed in resin and taken from a digital CT scan produced by Digits2Widgets

TC-2 digital loom: designed and developed by Tronrud Engineering.

Computer controlled hand loom especially designed to suit designers and artists. It is also ideal for rapid prototyping, can also produce customise designs, technical weaves and the production of high end textiles. In addition the loom is a sketchpad for ideas and concepts to determine whether it be a fine art or functional textiles.

Digitally woven carbon fibre samples: manufactured by Lexus for the LPA

- Roof rail: A lightweight component that runs either side of the windscreen and forms part of the roof.

- Crush rail: the important part of the car's crumple zone. It is among a safety feature designed to protect the driver by absorbing energy in the event of a crash.

- Carbon fibre blanket: an example of a digitally woven carbon fibre material.

Double sided pattern: designed by House of Production produced by CNCMYMODEL from shapeless hardwood using a three-axis miling machine.

The initial submissions

60 different designs which have been 3D printed, rapid prototype models of the unsuccessful entries for a competition.

Form left to right are the variety of designs from:

Alexander Purcell Rodrigues

Harry Owen

Damien Jamet

Stephen Tierney

Veronica Massoud

Jeremry Grove

Liam de la Bedoyere

Charles Trevelyan

Casa Estudio...

Andres Ros Soto And Giles round

These images show the winning design by Je-Uk Kim, after more than 10'000 votes it was selected as the crowd's favourite. The design took the features from classical Georgian furniture also from the lovebird. Kim's design matched the brief exactly creating a sofa which was functional and also compact adapting to moden life.

Moden designs for lights and pen cases.

This display of materials and fabric every different part represents a different section (templates) to create the trainer (shown In the foreground).

Chubby chair: designed by Dirk Vander Kooij

Flow Open Rocking chair: designed also by Dirk Vander Kooij

This idea rose when Kooij studed at The Design Academy in Eindhoven. He combind different techniques automated but a very flexible process. He chose to use a Robot to produce the collection of furniture from recycled scrap plastic pellets which originally was from refrigerator interiors.

Other moden designs.

The design museum has made me think about other new moden designs and not just the normal mundane ideas. I enhanced my knowledge of understanding the diffent development stages on a product an that it is different for that individual product. The product which are made need to have elements for from and function the product wouldn't be successful if mass produced etc...

No comments:

Post a Comment